What is needed to begin work?

By the agreed-upon time, we expect the client to send an order letter and final print-ready pdf files. In order to make sure that the pdf being sent to the printing house are correctly formatted, please follow the pre-printing guidelines. If colour printing is needed, take into account the necessary ICC profiles of the different paper types.

Please choose the right ICC profile for your paper type.

How to use profiles in photoshop

Uncoated Munken Kristall Rough

The profiles behave differently. While using the profiles, please pay attention to the changes in the picture. Use the profile that best fits your needs.

For a correctly measured cover, ask the sales manager who made the quote for the job in question for a diagram.

If you need further assistance you can always ask our sales department for help.

How to send the files to the printing house?

The files can be sent by email to repro@trt.ee or uploaded to the FTP server. You can also send files using WeTransfer, Dropbox or another similar service provider. We can only accept projects in CMYK or CMYK and spot-colour print-ready composite pdf file format, which have preferably been through a print preflight check. To avoid problems, we recommend using pdf version 1.3 (PDF standard PDF/X-1a:2001).

The clean format of the publication must be centered on the pdf page, with no cutting marks or marks located at least 5 mm outside the format. The file must contain the name of the work (in the case of a book, its title, but not the name of the author) and page numbers. If a revised page needs to be submitted at a later time, the printing house must be informed immediately. The new page’s file name must contain the word “new”. If the printing plates have already been finished, an additional cost will be charged in order to make the corrections.

The file can be uploaded to the general folder on the FTP-server

ftp.trt.ee

User: klient

Password: klient

Immediately after uploading the file, send a notification to repro@trt.ee. For repeat customers, we recommend creating a personal folder. For creating a user name and password, please email thea.sepman@trt.ee. Upload files in the folders already present on the FTP server, not just in the general folder. The creation, naming, and deleting of folders can only be done by Tallinn Book Printers.

File checking

Colour profiles

Colour profiles

To accomplish the optimal printing result, it is necessary to use the correct colour profile. That also requires selecting the right ICC profile based on the paper being used. That profile must be used from the very beginning in Photoshop when processing colour pictures. When printing black and white pictures on coated paper, use Dot Gain 10-15% and on uncoated paper 20-25%. ICC profiles can be found HERE.

How does file checking happen in the printing house?

How does file checking happen in the printing house?

On the printing house’s side, the technical check of the file or “preflight” happens using Enfocus PitStop Professional 2018. If there are problems with the file (incorrect format, low-resolution pictures, colour work in RGB, etc.), the client is contacted and asked to make corrections. Once the file has been fixed, the work progresses to the next step, assembling. After that, the EPSON 9800 plotter prints a proof, and when that has been checked, it’s time for the printing plates.

What kind of proofs can the client get before printing?

What kind of proofs can the client get before printing?

Digital proofs will be sent to the client only if it was requested at the time of the order. The files that have been checked by the printing house will be sent as digital proofs via email or uploaded to the FTP server.

A notification will be sent to the desired address and then we wait for some timely feedback. Getting a digital proof gives the client one last chance to look over the file and if needed, to swap out pages. In this stage, there is no charge for making changes. However, if changes need to be made in the next steps (assembling, proofs, printing plates) then charges will be added according to the situation.

Colour proofs

Colour proofs

Colour proofs include the book’s cover, dust jacket, and illustrations for colour checking. If a colour proof is needed, it should be arranged with the sales manager at the time of the order. Printouts of the cover and pages are made on a calibrated ink printer EPSON 7800. The printouts meet ECI (European Colour Initiative www.eci.org) standards. It must still be said that due to the differences between the colour plotter and the printing presses (including the different printing paper and lamination and lacquer) there may be slight differences in the colour tones between the proof and the final product.

We recommend returning us colour proofs issued to clients as soon as possible because they must be at hand during printing for quality control.

Preparation work

One of the prerequisites for producing a quality book that meets the client’s expectations is proper printing preparation. If preparation is inadequate, the printing house can’t significantly improve the result in later steps (printing and binding). Print technology is largely regimented by standards and guidelines, so the best way to get a quality result is to follow them as closely as possible. If any questions arise during preparation work, we are always ready to offer any help we can.

1. Image processing

- Use the ICC profile available at our homepage.

How to use profiles in photoshop

Uncoated Munken Kristall Rough

Partial colour sum in profiles:

gloss = 320%,

silk/matte = 300%,

uncoated = 270%.

- Picture files can be in TIFF, JPEG (max quality), PSD or EPS format.

- For a good printing result, picture resolution at scanning must be 300 dpi.

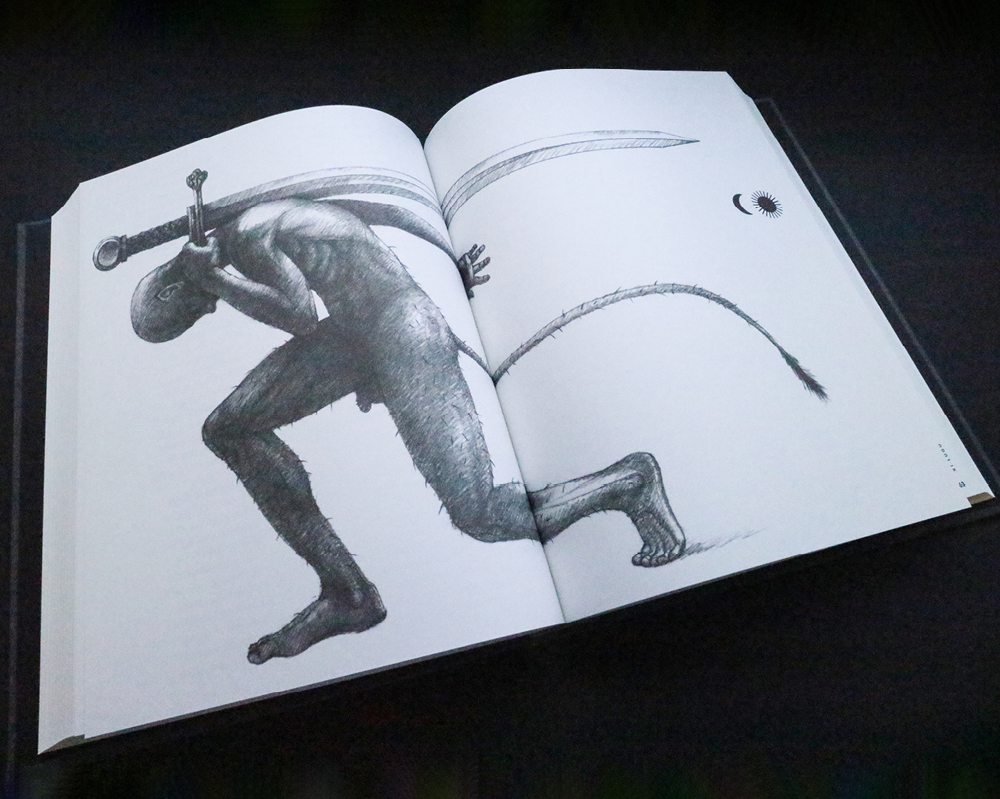

- Resolution of drawings must be between 800 and 1200 dpi.

- With photographs, light areas must have at least a 2% raster point (except with reflections of light or for artistic effect, where there may be no raster point).

- Dark areas of photos may have a raster point up to 95%.

- When using black texts or objects, avoid the use of 4-colour black, or rich black (other colours must be removed beneath the black).

- All image files must be converted in Photoshop (RGB → CMYK; RGB → GRAY; CMYK → GRAY).

- All colour illustrations must be in CMYK format (not RGB or Lab) before placement in the layout, except when printing is planned with SPOT-colours.

- All black and white half-tone images must be saved as grayscale images.

2. Design

- A 5 mm bleed must be added to the outer edge of the publication. An inside bleed is not required.

- Design elements which extend to the edges of the publication’s format must continue 5 mm over the cut edge so that imprecision in the measurement of the paper and any shifting caused by the post-production machines doesn’t leave plain white space at any of the edges of the final product.

NB! When using glue bindings, the design should account for at least 3-5 mm at the internal margin in order to prevent the design from being too close to the spine of the book, ensuring readability. - The distance of text or other important design elements from the cut edge of the publication must be at least 5 mm.

- Avoid the use of white (negative) lettering (knock-out) smaller than 8 points on coloured objects.

- The minimum recommended size for cursive lettering and lettering with finely drawn details is 9 points.

- Do not use the Hairline attribute or lines finer than .25 points.

3. Making a PDF

- We prefer composite pdf files that conform to PDF/X-1A standards which are created from a PS print file using Adobe Acrobat Distiller 5-8 on approved settings (PDF/X-1A) and preferably having undergone a preflight check.

- Preferably, files should be furnished with final formatting and crop marks. Crop marks must fall outside the cutting margin (5 mm from the final format)

- Presented files must include all colour pictures and elements in CMYK format (not RGB or Lab), except when printing is planned with SPOT colours.

- The file name must include at least as much of the name of the publication in order for it to be recognized by its name.

- The submitted files must be in the final print format (1:1 size), the pages must be in the correct order with blank pages, and two pages must not be side by side (spread).

- All fonts used in the design must be included in the files sent to the printing house.

4. Submission of work

Files can be sent by e-mail to repro@trt.ee or uploaded to the FTP server. Large files can also be transferred via WeTransfer, Dropbox, or another similar service. We only accept work as CMYK or CMYK and spot color ready-to-print composite PDFs and have preferably passed the preflight check. To avoid problems, it is recommended to use PDF version 1.3 (PDF standard PDF/X-1a:2001).

The clean format of the publication must be in the middle of the pdf page, without cut marks, not two pages side by side. The name of the submitted file must include the title of the work (in the case of a book, the title, but not the name of the author) and the page number(s). If a correction page needs to be sent later, the printing house must be informed immediately. The filename of the new page must contain the word “new.” If the printing plates are already made, an additional fee will be added for making corrections after this.

ftp.trt.ee

User: klient

Passwprd: klient

After uploading the files, send a notification to repro@trt.ee. For a personal user name and password to the FTP server, write to thea.sepman@trt.ee.

Materials and design

The choice of materials is a critical decision in the production of books and publications. Every step of the process, from design to final product, places different demand on the material. Frequently it ends up being a compromise, which inevitably is based upon not only the final goal for the creator, retailer, and consumer, but ultimately also on the characteristics of the material, the costs of printing, and time factors.

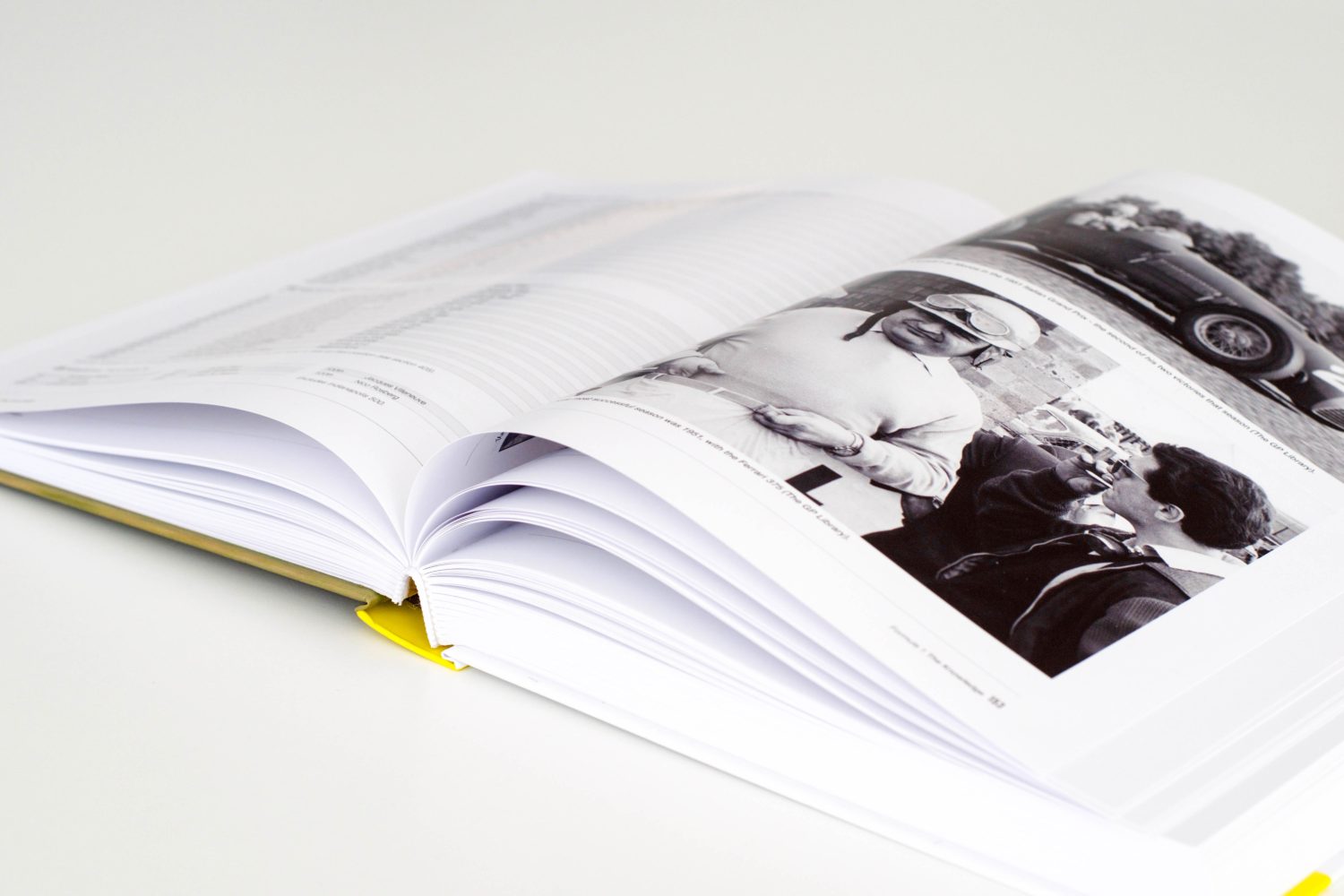

One of the most foundational aspects of a book artist’s design work is the paper – the source of the book’s idea and the basis of the final result. The message of the paper itself is vital to the publisher; its suitability for the target market, traditional appeal, profitability, etc. But no less important is the real existence of the paper at the time of printing. For the printing house, the important aspects of the paper are the harmonization of its technical qualities, both in printing and binding. The reader only sees the paper as the medium that conveys the printed text and pictures. In other words – paper touches us all and decides quite a bit.

Content formats and cover dimensions

The content of a book consists of pages of paper printed on both sides, which typically are bound in sections of 16 pages. There can also be sections of 8, 12, or 32 pages. The number of sheets on a section depends upon which fraction of the total page count is the basis for the book’s formatting and how and in what order the sections are folded together.

A sketch of the cover along with its measurements can only be ordered from the sales manager once the final draft’s format, the final number of pages, binding method, and type of paper being used have all been determined.

It is critical that all text, logos and other objects on the cover’s design are placed at least 5 mm from the edge of the cover’s final format.

NB! When designing the interior covers of glue-bound books, 8-10 mm must be accounted for the area that falls under the glue line!

Tükipoognal 8 lehekülge

Siia alla kuuluvad formaadid vahemikus:

> Laiusest 175 kuni 245 mm

> Kõrgusest 245 kuni 335 mm

Vt. trükipoogna ja montaazhi üldskeemi

Vt. vihikus 16 lk, üksteise sisse

Vt. vihikus 16 lk, üksteise kõrvale

Trükipoognal 12 lehekülge

Sobilik formaat ruudukujuliste raamatute trükiks.

Trükipoognal 16 lehekülge

Klassikaline trükipoogen. Siia alla kuuluvad trükiste formaadid vahemikus:

> Laiusest 125 kuni 170 mm

> Kõrgusest 170 kuni 240 mm

Vt. trükipoogna ja montaazhi üldskeemi

Vt. vihikus 16 lk, üksteise sisse

Vt. vihikus 16 lk, üksteise kõrvale

Vt. vihikus 32 lk, üksteise kõrvale

Trükipoognal 32 lehekülge

Üldlevinud taskuväljaannete formaat. Formaadid vahemikus:

> Laiusest 105 kuni 120 mm

> Kõrgusest 148 kuni 165 mm

Vt. trükipoogna ja montaazhi üldskeemi

Vt. vihikus 16 lk, üksteise sisse

Vt. vihikus 16 lk, üksteise kõrvale

Vt. vihikus 32 lk, üksteise kõrvale

FAQ

Can a single copy of a book be ordered from TRT?

Yes, if needed we can print just one copy. However, optimal pricing begins at about 300 copies.

How thick does foil printing need to be?

The minimum line width is 0.15mm. Unfortunately, we are not able to print a line thinner than that.

You offer a wide variety of paper. Do you keep all types of paper in stock?

The types that are in highest demand are always in our warehouse, but that assortment can change over time. Also, take note that the delivery of printed matter on some types of paper may take quite some time.

Contact

If you have any questions you can contact us. We will reply first chance we get.